THM RECYCLING MACHINES

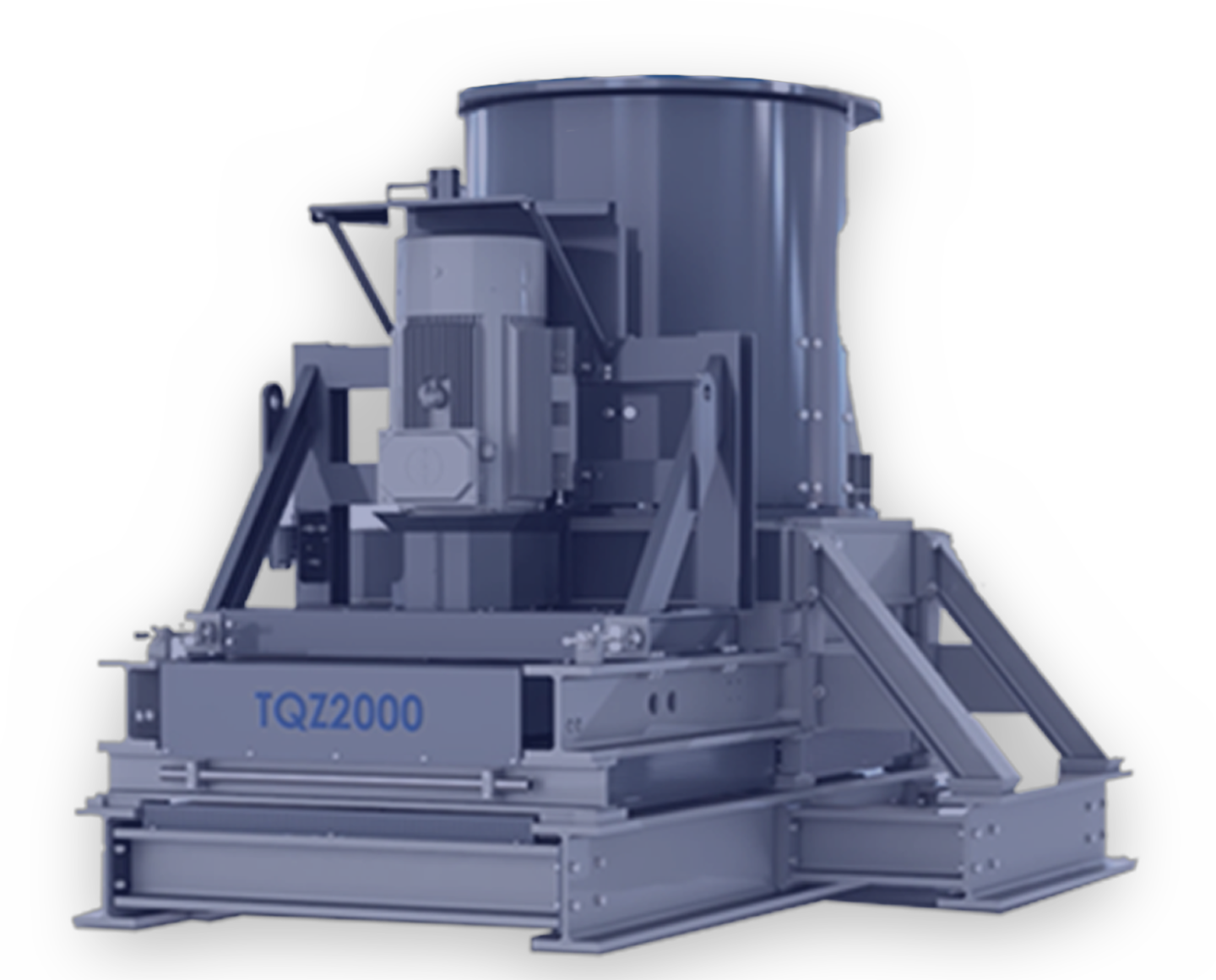

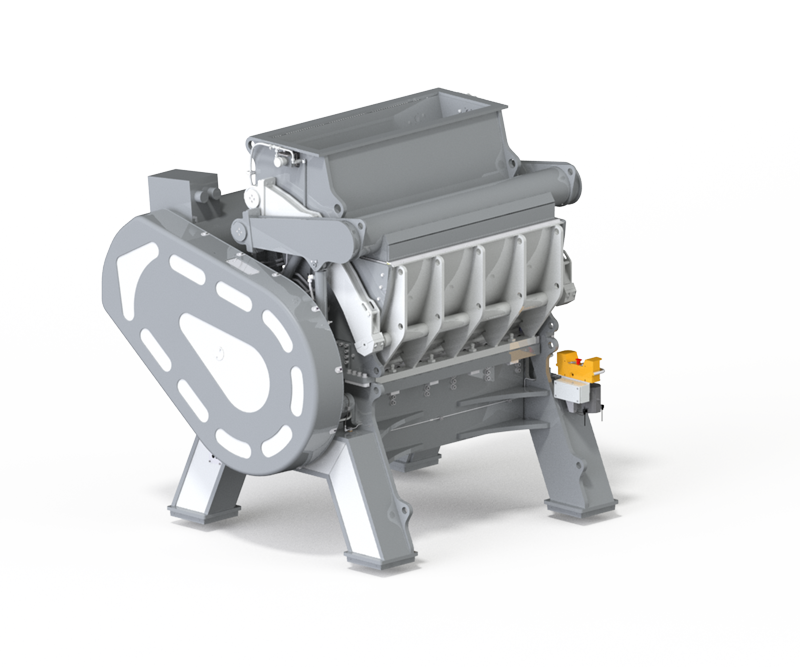

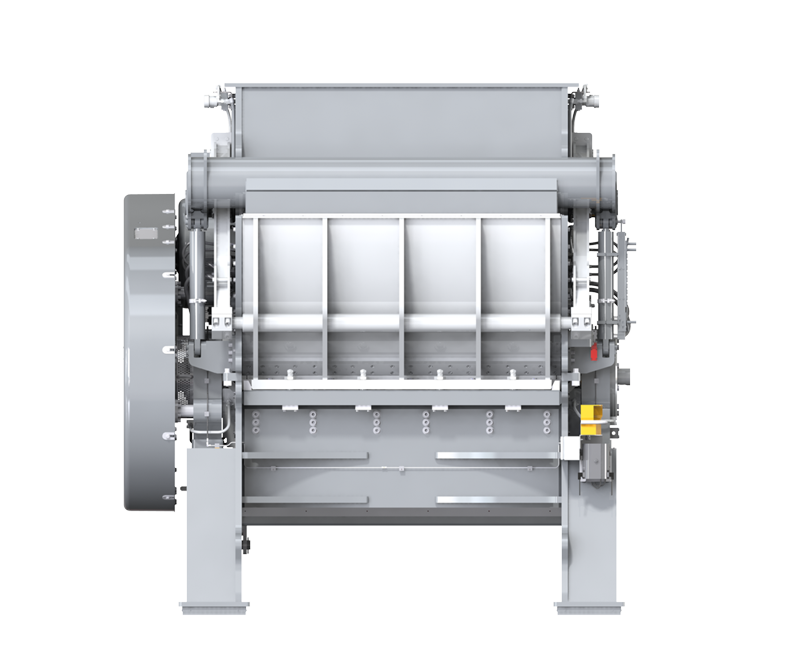

AG Granulator

Used tires

Textile

Matrazen

| Type | AG1608 | AG2008 | AG2808 |

|---|---|---|---|

| Inlet opening | 1650 x 615mm | 2020 x 615mm | 2830 x 615mm |

| Blade cutting circle | 785mm | 785mm | 785mm |

| Rotor speed | 250 rpm | 250 rpm | 120 - 200 rpm |

| Number of blades | 40 rotor blades and 8 stator blades | 50 rotor blades and 10 stator blades | 70 rotor blades and 14 stator blades |

| Drive power | 250 kW | 315 kW | 2 x 250kW / 2 x 315kW |

| Hydraulic unit | 15 kW | 15 kW | 15 kW |

| Dimensions | 2985 x 2785 x 3360mm (L x W x H) | 2985 x 3200 x 3360mm (L x W x H) | 2985 x 4320 x 3360mm (L x W x H) |

| Weight | approx. 24 t | approx. 27 t | approx. 36.5 t |

Made for maximum throughput

THM Granulators know only one thing: throughput, throughput and more throughput. Their range of application is uniquely broad:

- Plastics

- Cable waste

- Household/commercial/industrial and bulky waste

- Aluminium turning , milling chips

- Oil filters

- Steel and plastic drums

- Paper

- Electrical and electronic waste (electric motors up to 1/5 kg, transformers up to 3 kg)

- Car & HGV tyres

- Cast parts and metal profiles

- Others

- and much more...

- Consistently high cutting qualities thanks to readjustable blade blocks

- High power reserves for shredding even solid metals

- High throughput of up to 20 t/h

- Demand-driven offer: Working widths of 1,600 and 2,000 mm length and 250kW or 315kW

[TextMaterialfraktionen]

- Textiles

- Aluminium

- Transformers

- etc.

- Korngrößenfraktionen: 10 mm bis 100 mm

- Electric motors

- Cable

Technical specifications

| Type | AG1608 | AG2008 |

|---|---|---|

| Inlet opening | 1650 x 615mm | 2020 x 615mm |

| Blade cutting circle | 785mm | 785mm |

| Rotor speed | 250 rpm | 250 rpm |

| Number of blades | 40 rotor blades and 8 stator blades | 50 rotor blades and 10 stator blades |

| Drive power | 250 kW | 315 kW |

| Hydraulic unit | 15 kW | 15 kW |

| Dimensions | 2985 x 2785 x 3360mm (LxWxH) | 2985 x 3200 x 3360mm (LxWxH) |

| Weight | approx. 24 t | approx. 27 t |

| Type | AG2808 |

|---|---|

| Inlet opening | 2830 x 615mm |

| Blade cutting circle | 785mm |

| Rotor speed | 120 - 200 rpm |

| Number of blades | 70 rotor blades and 14 stator blades |

| Drive power | 2 x 250kW / 2 x 315kW |

| Hydraulic unit | 15 kW |

| Dimensions | 2985x4320x3360mm (LxWxH) |

| Weight | approx. 36.5 t |

Areas of application

Made for maximum throughput

THM Granulators know only one thing: throughput, throughput and more throughput. Their range of application is uniquely broad:

- Plastics

- Cable waste

- Household/commercial/industrial and bulky waste

- Aluminium turning , milling chips

- Oil filters

- Steel and plastic drums

- Paper

- Electrical and electronic waste (electric motors up to 1/5 kg, transformers up to 3 kg)

- Car & HGV tyres

- Cast parts and metal profiles

- Others

- and much more...

Advantages

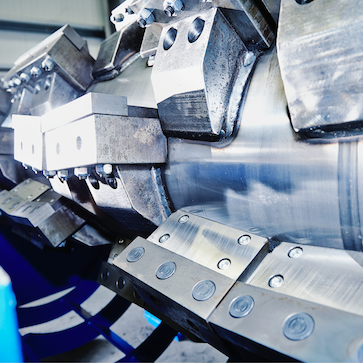

- Consistently high cutting qualities thanks to readjustable blade blocks

- High power reserves for shredding even solid metals

- High throughput of up to 20 t/h

- Demand-driven offer: Working widths of 1,600 and 2,000 mm length and 250kW or 315kW

Material fractions

[TextMaterialfraktionen]

- Textiles

- Aluminium

- Transformers

- etc.

- Korngrößenfraktionen: 10 mm bis 100 mm

- Electric motors

- Cable

" The specialist for substitute fuels "

Glutton with biting qualities

The universal granulator for every application

The extremely robust AG Granulators were developed for metal shredding, but also impress with their exceptional shredding qualities for other materials such as cable scrap, plastic waste & Co. Regardless of whether the machines are shredding metal, recovering recyclable materials or processing refuse-derived fuels - every granulator does its job with flying colours.

All components are designed for maximum load capacity. A prime example is the rotor of the machine: Forged and specially rolled, it is made for demanding continuous use even in the tough working environment of scrap processing.

Technische Spezifikationen

| Type | AG1608 | AG2008 | AG2808 |

|---|---|---|---|

| Inlet opening | 1650 x 615mm | 2020 x 615mm | 2830 x 615mm |

| Blade cutting circle | 785mm | 785mm | 785mm |

| Rotor speed | 250 rpm | 250 rpm | 120 - 200 rpm |

| Number of blades | 40 rotor blades and 8 stator blades | 50 rotor blades and 10 stator blades | 70 rotor blades and 14 stator blades |

| Drive power | 250 kW | 315 kW | 2 x 250kW / 2 x 315kW |

| Hydraulic unit | 15 kW | 15 kW | 15 kW |

| Dimensions | 2985 x 2785 x 3360mm (L x W x H) | 2985 x 3200 x 3360mm (L x W x H) | 2985 x 4320 x 3360mm (L x W x H) |

| Weight | approx. 24 t | approx. 27 t | approx. 36.5 t |

Einsatzbereiche

Made for maximum throughput

THM Granulators know only one thing: throughput, throughput and more throughput. Their range of application is uniquely broad:

xyz-ips snippet=”List-Einsatzbereiche”

Vorteile

- Hohe Durchsatzleistung

- Gleichbleibende hohe Schnittqualität dank nachjustierbarer Messerblöcke

- Extra große Schwungscheibe

- Hohe Stabilität und ruhiger Lauf infolge eines hohen Maschinengewichts Hydraulischer Nachdrückeinheit, daher selbst leichtes Material problemlos zerkleinerbar

- Leicht wechselbare Verschleißteile

Materialfraktionen

- Definierte Outputgröße durch einfach zu wechselnde Siebsegmente

- Granulat und Flakes 20 – 100 mm