THM RECYCLING MACHINES

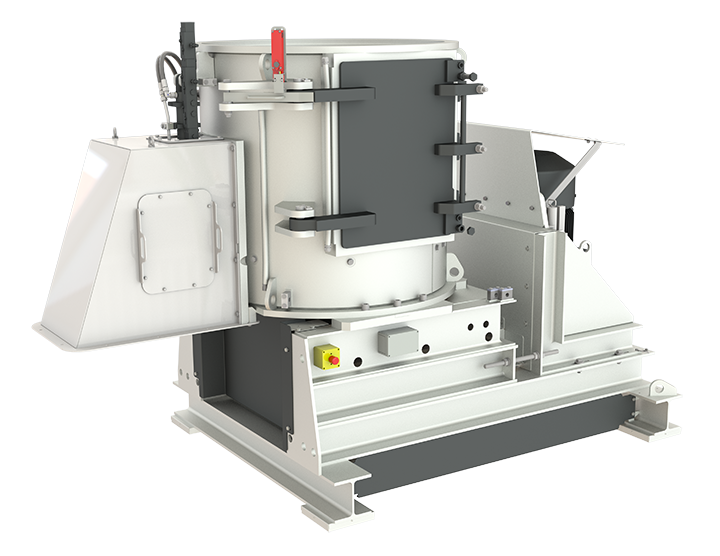

BIO-TQZ Turbo-Crusher

Used tires

Textile

Matrazen

| Type | BIO-TQZ900 | BIO-TQZ1200 |

|---|---|---|

| Inlet opening | Ø900mm | Ø1200mm |

| Rotor speed | 1200 rpm | 900 rpm |

| Drive power: | 55-75 kW | 75-90 kW |

| Hydraulic unit | 4 kW | 4 kW |

| Dimensions | 2720 x 1800 x 2290mm (L x W x H) | 2890 x 1800 x 2270mm (L x W x H) |

| Weight | approx. 3.5 t | approx. 5 t |

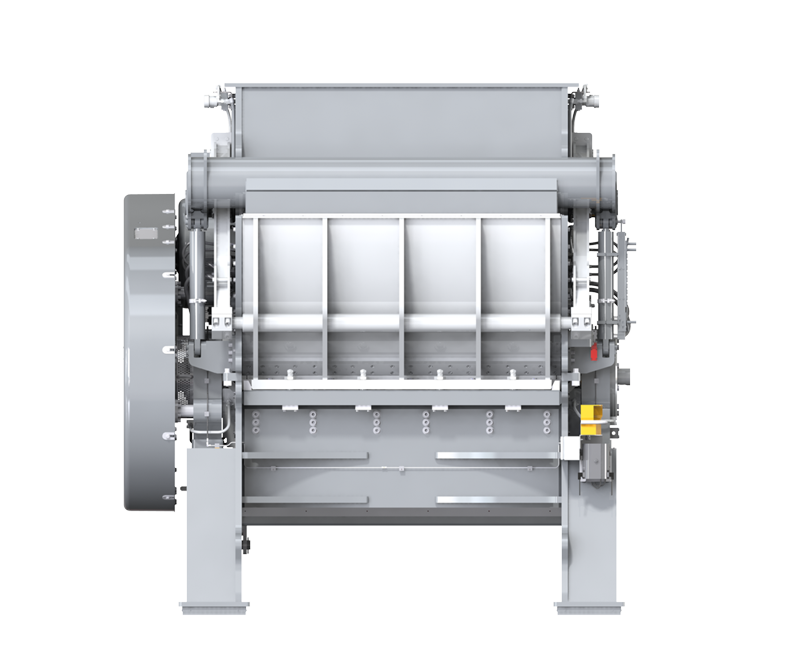

Guaranteed perfect fermentation substrates

THM's Bio-TQZ prepares the input materials or organic waste for the biogas plant into a homogeneous substrate. Fractions that are interfering substances or can form a floating layer are separated from the biomaterial. The Bio-TQZ processes the following materials very efficiently:

- etc.

- Energy crops (maize, grass, sunflowers, sugar beet etc.)

- Organic waste

- Food waste

- Packaged food

- Fruit and vegetables past their expiry date

- Slurry, cattle, horse manure with straw content

- Higher economic efficiency due to shorter residence times of the substrate in the fermenter and a significantly increased gas yield

- High throughput of up to 25 t/h

- Additional cost saving by replacing the mixer

- Utilisation of even difficult input materials

- No floating layer in the fermenter

- Reliable separation of contaminants such as food packaging/plastic bags from the biomaterial

[TextMaterialfraktionen]

- Homogeneous, pumpable substrate of any consistency, through adjustable residence time, and addition of liquids

Technical specifications

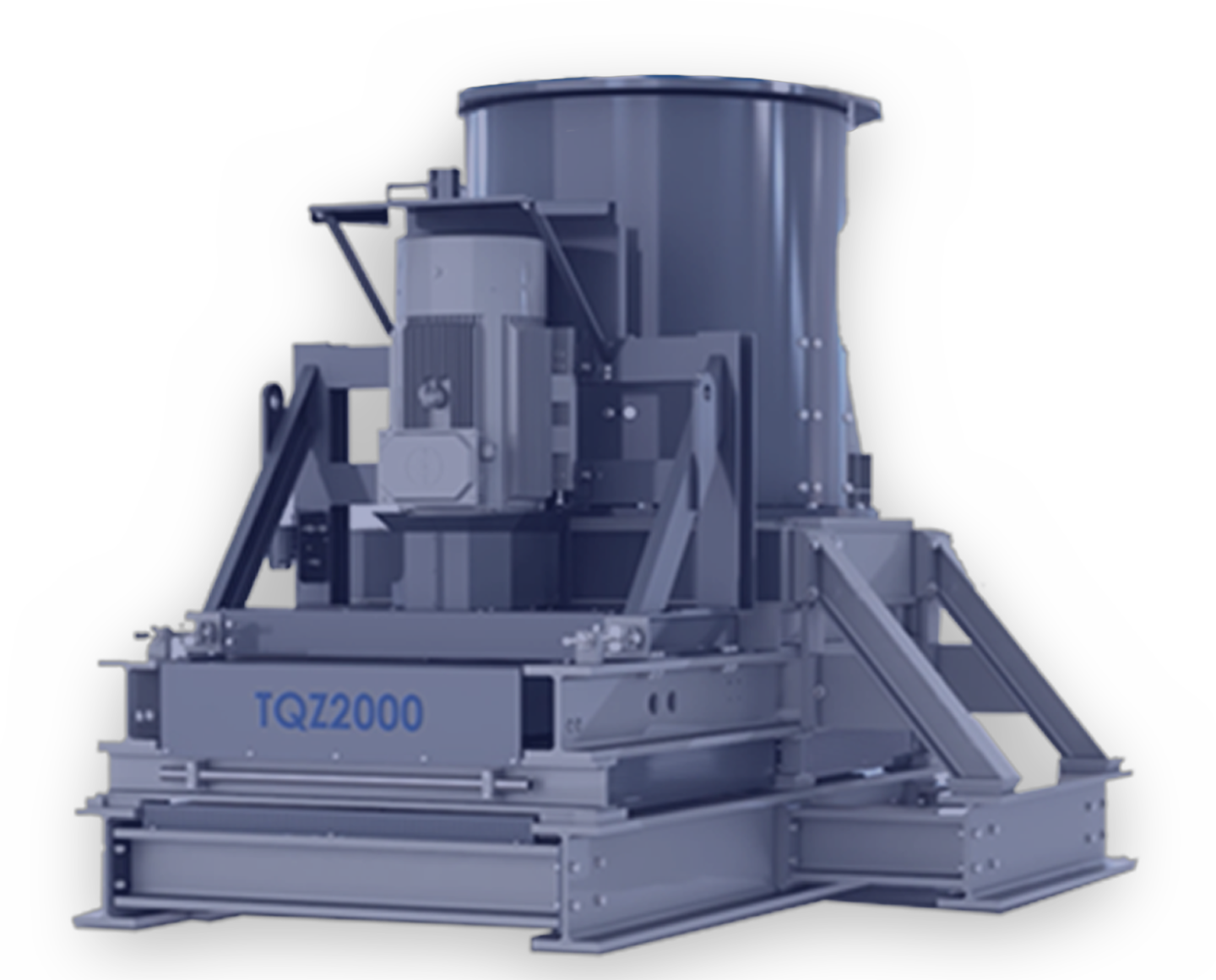

| Type | TQZ900BIO |

|---|---|

| Inlet opening | Ø900mm |

| Rotor speed | 1200 rpm |

| Drive power: | 75 kW |

| Hydraulic unit | 4 kW |

| Dimensions | 2720x1800x2290mm (LxWxH) |

| Weight | approx. 3.5 t |

| Type | TQZ1200BIO |

|---|---|

| Inlet opening | Ø1200mm |

| Rotor speed | 900 rpm |

| Drive power: | 90 kW |

| Hydraulic unit | 4 kW |

| Dimensions | 2890x1800x2270mm (LxWxH) |

| Weight | approx. 5 t |

Areas of application

Guaranteed perfect fermentation substrates

THM's Bio-TQZ prepares the input materials or organic waste for the biogas plant into a homogeneous substrate. Fractions that are interfering substances or can form a floating layer are separated from the biomaterial. The Bio-TQZ processes the following materials very efficiently:

- etc.

- Energy crops (maize, grass, sunflowers, sugar beet etc.)

- Organic waste

- Food waste

- Packaged food

- Fruit and vegetables past their expiry date

- Slurry, cattle, horse manure with straw content

Advantages

- Higher economic efficiency due to shorter residence times of the substrate in the fermenter and a significantly increased gas yield

- High throughput of up to 25 t/h

- Additional cost saving by replacing the mixer

- Utilisation of even difficult input materials

- No floating layer in the fermenter

- Reliable separation of contaminants such as food packaging/plastic bags from the biomaterial

Material fractions

[TextMaterialfraktionen]

- Homogeneous, pumpable substrate of any consistency, through adjustable residence time, and addition of liquids

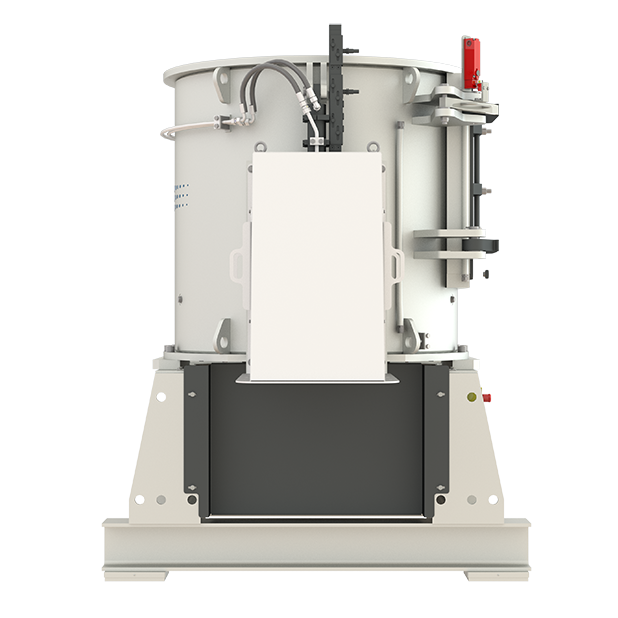

" Impact shredder for biogenic materials. "

Turbocharge your biogas plant

The successful model for a high gas yield

Quality makes all the difference in biogas production. If you want to produce biogas efficiently, you need substrates that produce as much methane as possible in the fermenter. THM's BIO-TQZ Turbo-Crusher delivers the required qualities. Unlike conventional shredders, the BIO-TQZ does not shred the input materials with blades, but using a rotating chain.

The chain shreds the plants and plant debris and thoroughly breaks down their cell structures. The result is a homogeneous substrate that is decomposed more quickly by bacteria and yields a significantly higher gas yield. Foreign substances are separated and can be removed afterwards.

Technische Spezifikationen

| Type | BIO-TQZ900 | BIO-TQZ1200 |

|---|---|---|

| Inlet opening | Ø900mm | Ø1200mm |

| Rotor speed | 1200 rpm | 900 rpm |

| Drive power: | 55-75 kW | 75-90 kW |

| Hydraulic unit | 4 kW | 4 kW |

| Dimensions | 2720 x 1800 x 2290mm (L x W x H) | 2890 x 1800 x 2270mm (L x W x H) |

| Weight | approx. 3.5 t | approx. 5 t |

Einsatzbereiche

Guaranteed perfect fermentation substrates

THM's Bio-TQZ prepares the input materials or organic waste for the biogas plant into a homogeneous substrate. Fractions that are interfering substances or can form a floating layer are separated from the biomaterial. The Bio-TQZ processes the following materials very efficiently:

xyz-ips snippet=”List-Einsatzbereiche”

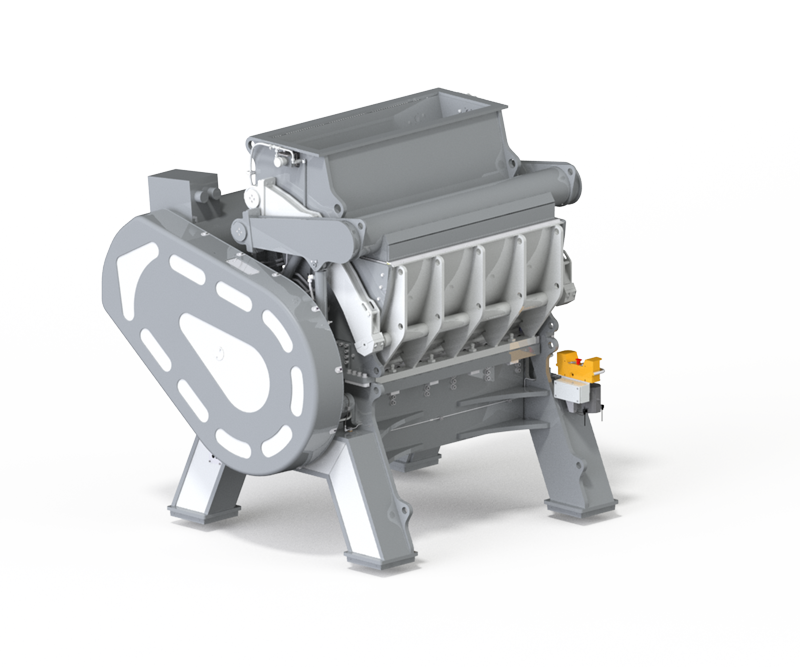

Vorteile

- Hohe Durchsatzleistung

- Gleichbleibende hohe Schnittqualität dank nachjustierbarer Messerblöcke

- Extra große Schwungscheibe

- Hohe Stabilität und ruhiger Lauf infolge eines hohen Maschinengewichts Hydraulischer Nachdrückeinheit, daher selbst leichtes Material problemlos zerkleinerbar

- Leicht wechselbare Verschleißteile

Materialfraktionen

- Definierte Outputgröße durch einfach zu wechselnde Siebsegmente

- Granulat und Flakes 20 – 100 mm