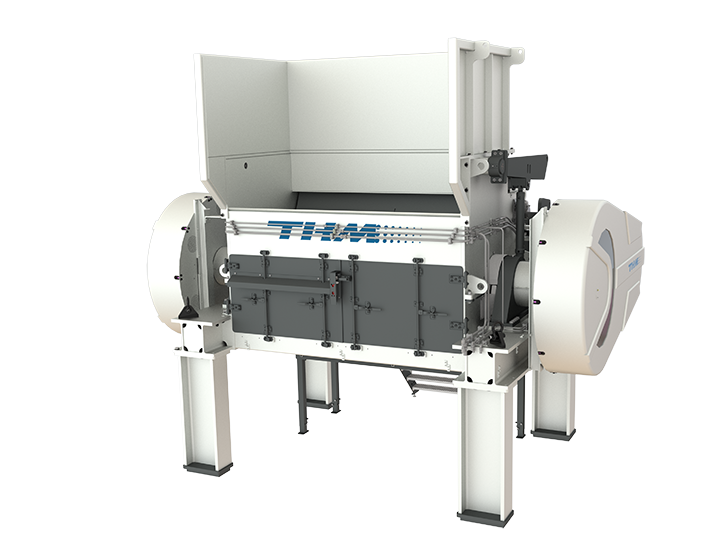

THM RECYCLING MACHINES

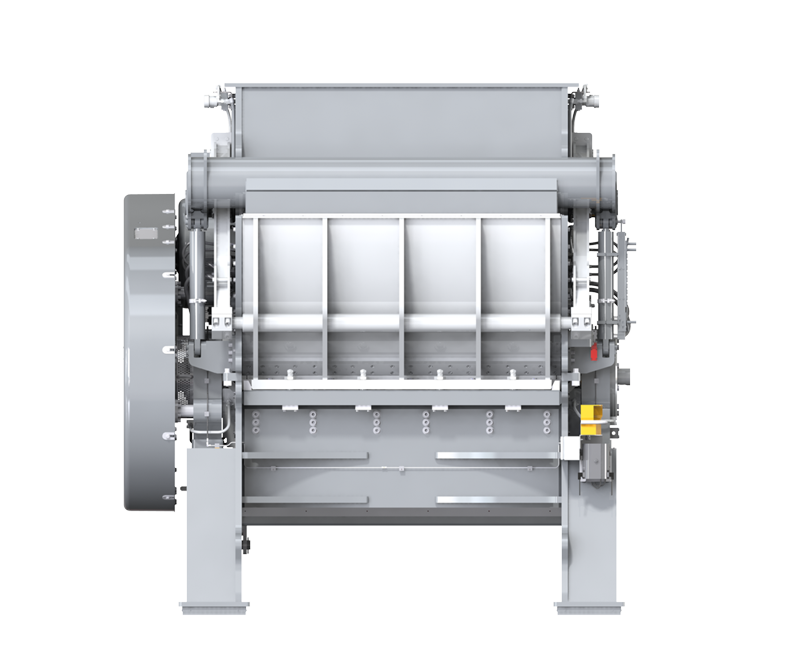

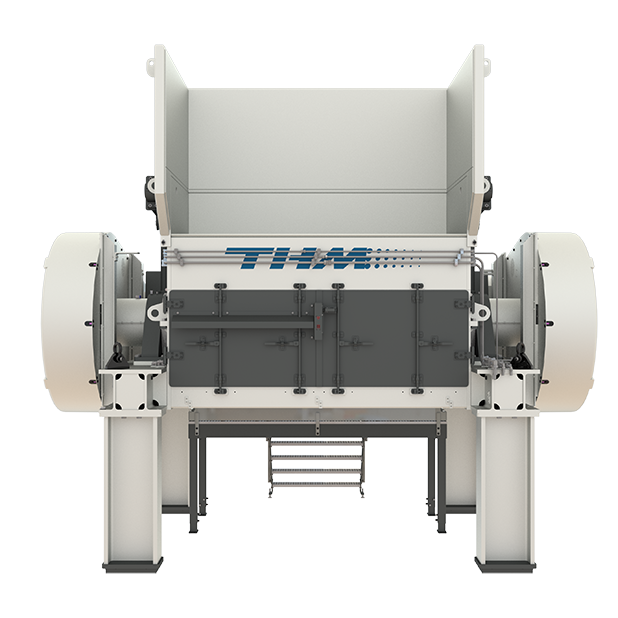

XG Universal Granulator

Used tires

Textile

Matrazen

| Type | XG2400 |

|---|---|

| Inlet opening | 2400 x 1500mm |

| Blade cutting circle | 785mm |

| Rotor speed | 60-80 rpm (FU controlled) |

| Number of blades | 60 rotor blades and 12 stator blades |

| Drive power: | 2 x 110 kW (12pol) |

| Hydraulic unit | 22 kW |

| Dimensions | 4260 x 5150 x 4830mm (L x W x H) |

| Weight | approx. 43 t |

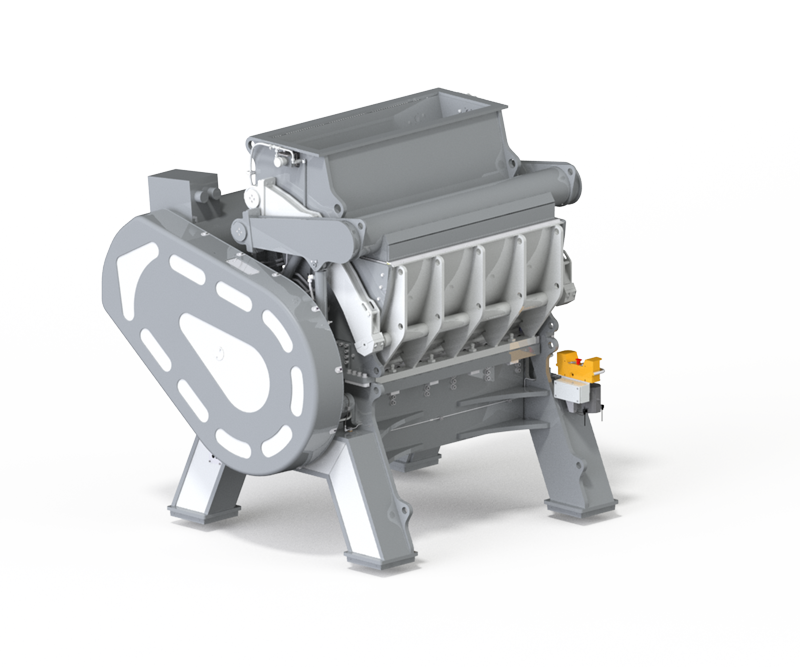

Created for demanding continuous use

A prime example is the machine's rotor: forged and specially rolled, it is made for demanding continuous use even in the toughest working environment. The machine processes the following materials effortlessly:

- Metals

- Plastics

- Textiles

- Cardboard and paper

- Waste wood

- Rejects

- Domestic/commercial and industrial waste

- Easily replaceable wearing parts

- High throughput

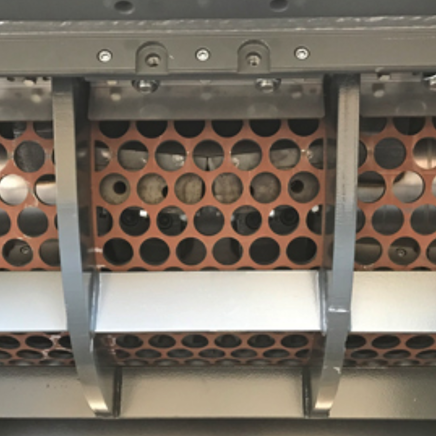

- Consistently high cutting quality thanks to readjustable blade blocks

- Extra large flywheel

- High stability and smooth running due to a high machine weight

- Hydraulic pressure unit, therefore even light material can be shredded without any problems

[TextMaterialfraktionen]

- Defined output size through easy to change sieve segments

- Granulate and flakes 20 - 100 mm

Technical specifications

| Type | XG2400 |

|---|---|

| Inlet opening | 2400 x 1500mm |

| Blade cutting circle | 785mm |

| Rotor speed | 60-80 rpm (FU controlled) |

| Number of blades | 60 rotor blades and 12 stator blades |

| Drive power: | 2 x 110 kW (12pol) |

| Hydraulic unit | 22 kW |

| Dimensions | 4260 x 5150 x 4830mm (L x W x H) |

| Weight | approx. 43 t |

Areas of application

Created for demanding continuous use

A prime example is the machine's rotor: forged and specially rolled, it is made for demanding continuous use even in the toughest working environment. The machine processes the following materials effortlessly:

- Metals

- Plastics

- Textiles

- Cardboard and paper

- Waste wood

- Rejects

- Domestic/commercial and industrial waste

Advantages

- Easily replaceable wearing parts

- High throughput

- Consistently high cutting quality thanks to readjustable blade blocks

- Extra large flywheel

- High stability and smooth running due to a high machine weight

- Hydraulic pressure unit, therefore even light material can be shredded without any problems

Material fractions

[TextMaterialfraktionen]

- Defined output size through easy to change sieve segments

- Granulate and flakes 20 - 100 mm

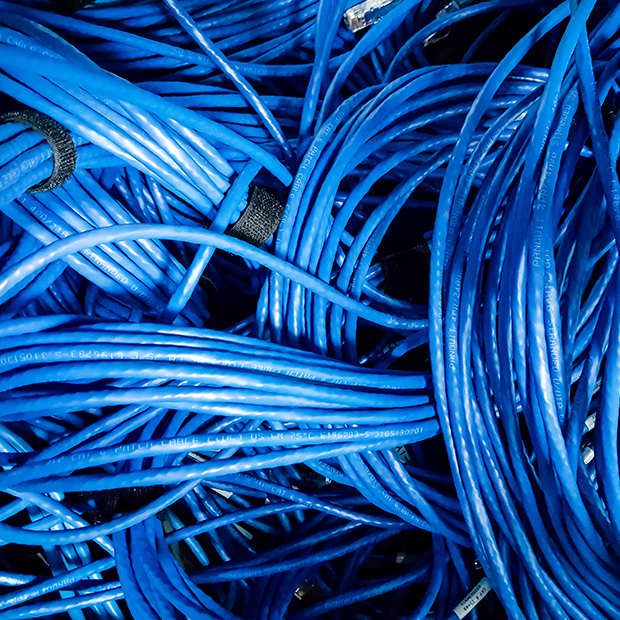

" For single-stage shredding of metals, cables, wood, textiles, rubber, etc. "

Can be used universally for single-stage shredding

The Universal Granulator XG from THM is used for single-stage size shredding of a wide range of different materials. Whether wood, substitute fuel, cable scrap, electronic waste, metals or other materials, the Universal Granulator XG gets it small. Thanks to the large inlet opening, the Universal Granulator can also shred very large and bulky parts to the desired final size in a single operation.

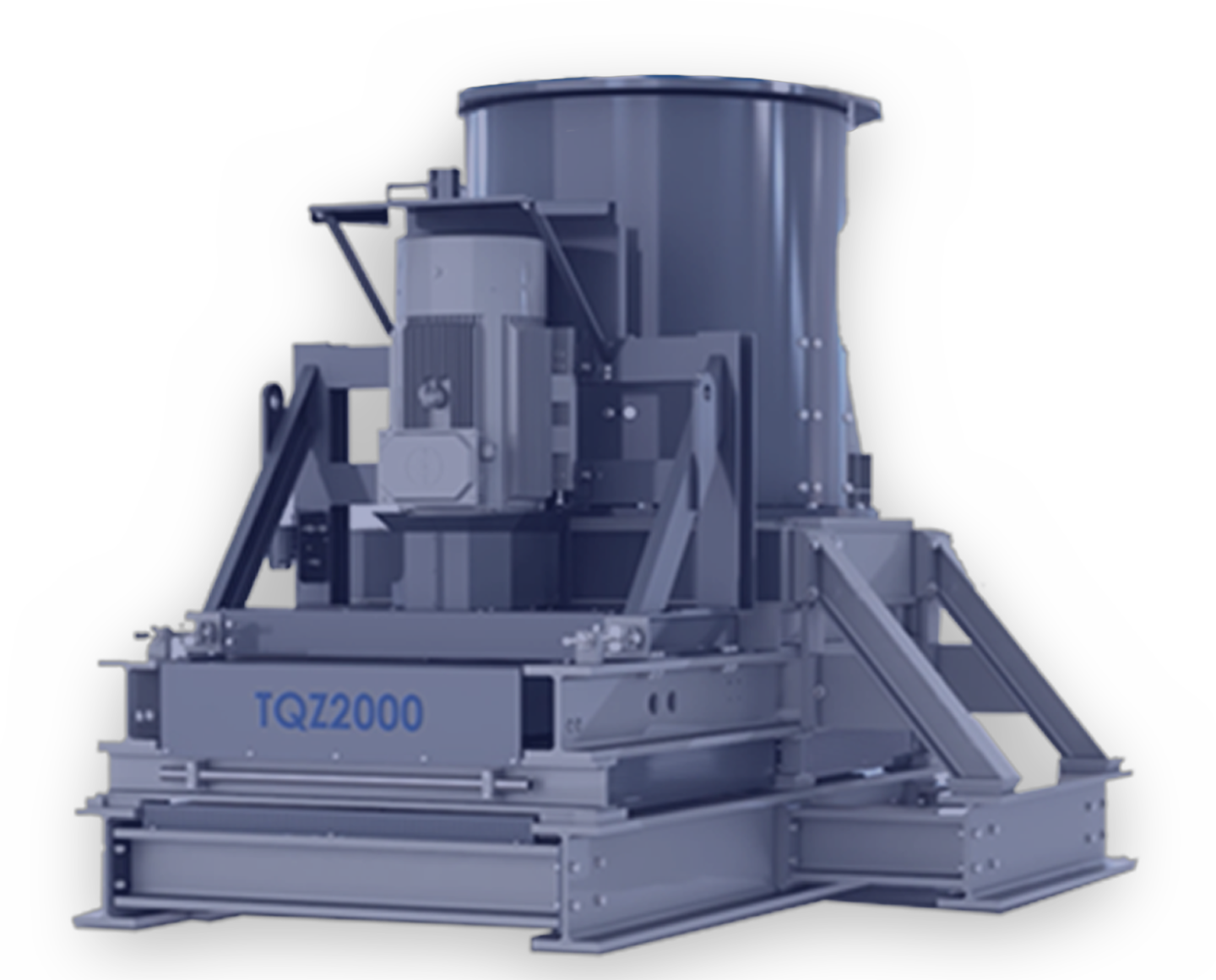

A segmented granulating sieve is fitted below the rotor. The hydraulically swivelling sieve basket enables quick and easy changing of the sieve segments. The output grain size is determined by the selection of the sieve hole size.

Technische Spezifikationen

| Type | XG2400 |

|---|---|

| Inlet opening | 2400 x 1500mm |

| Blade cutting circle | 785mm |

| Rotor speed | 60-80 rpm (FU controlled) |

| Number of blades | 60 rotor blades and 12 stator blades |

| Drive power: | 2 x 110 kW (12pol) |

| Hydraulic unit | 22 kW |

| Dimensions | 4260 x 5150 x 4830mm (L x W x H) |

| Weight | approx. 43 t |

Einsatzbereiche

Created for demanding continuous use

A prime example is the machine's rotor: forged and specially rolled, it is made for demanding continuous use even in the toughest working environment. The machine processes the following materials effortlessly:

xyz-ips snippet=”List-Einsatzbereiche”

Vorteile

- Hohe Durchsatzleistung

- Gleichbleibende hohe Schnittqualität dank nachjustierbarer Messerblöcke

- Extra große Schwungscheibe

- Hohe Stabilität und ruhiger Lauf infolge eines hohen Maschinengewichts Hydraulischer Nachdrückeinheit, daher selbst leichtes Material problemlos zerkleinerbar

- Leicht wechselbare Verschleißteile

Materialfraktionen

- Definierte Outputgröße durch einfach zu wechselnde Siebsegmente

- Granulat und Flakes 20 – 100 mm